3D Printing is Not a Fad: Why this technology should be on your shop floor

If you are not at least experimenting with additive manufacturing, also known as 3D printing, in your manufacturing business, your competitors are. In addition, cost can’t be an excuse because 3D printing technology has gotten downright cheap. You can find dozens of these printer models for less than $1000 on Amazon.

Industry Week reported in February that the World Economic Forum (WEF) named Fast Radius’ new Chicago facility as one of nine top smart factories, thanks to speed and quality. Fast Radius embraces additive manufacturing along with CNC machining and injection molding, providing parts and services from design to deliver.

Why should you look to 3D Printing?

These pioneers have created factories that have 20-50% higher performance and create a competitive edge,

says Enno de Boer, partner and global head of manufacturing at McKinsey & Co., which worked with the WEF on the selections of the nine winners. They are thinking

scale,

acting agile

and resetting the benchmark.

When considering game-changing technologies such as robotics and 3D Printing, Fast Radius CEO, Lou Rassey, says, The beauty of them is that they are accessible.

He adds, Any machine shop or manufacturer today can embrace applications such as printing tools and fixture and jigs.

Rassey cautions, Every manufacturer might need to reflect on how these new tools might displace their method of fabrication and see if they need to make some new investments in some of these tools.

Did we say game-changing technology? Hyperbole? Hardly!

For one aerospace customer that had a critical need for a spare part, we were able to receive an order and fabricate it using additive manufacturing, validate it and get it halfway around the world all within 48 hours, when conventionally manufactured, it would have taken 48 days,

Rassey says.

In another instance, Fast Radius’ additive service produces one-third of the bill of materials for one automation company’s new product. And, in yet another, Fast Radius created a virtual parts warehouse (parts exist only digitally until needed) comprising 3000 items for a heavy equipment manufacturer, which really adds up over time.

The rule of thumb is the cost of storing a part is 25% of the total cost of part,

Rassey explains. Therefore, a product manufacturer that needs to store parts for decades or more spends more on storage than production. And instead of making 20 of something, just make one.

These are real meaningful numbers when you look at the cost of the supply chain,

he adds.

According to the International Data Corporation (IDC), the 3D printing market is expected to bring in nearly $35 billion in revenue by 2020 compared to $16 billion just four years ago.

What is 3D printing?

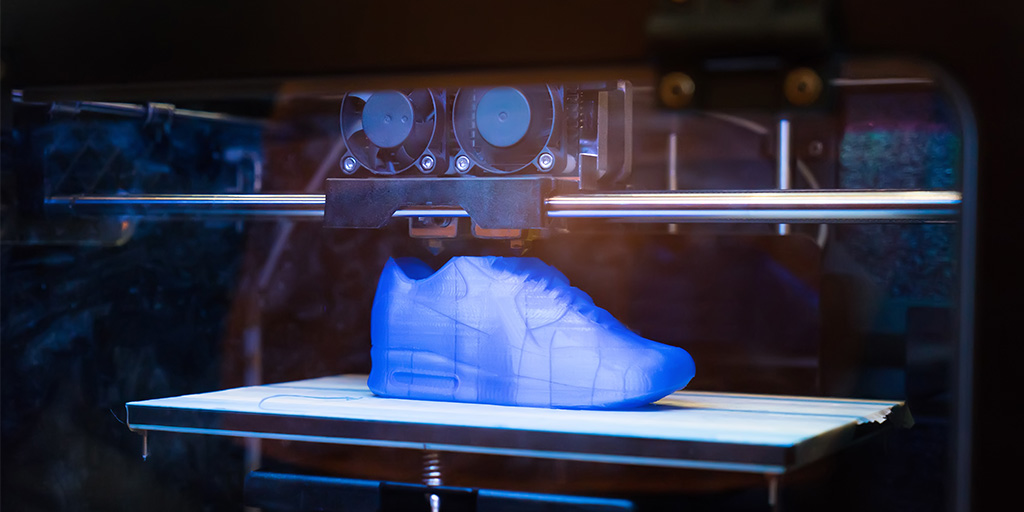

3D printing or as mentioned above, additive manufacturing, is a process of making three-dimensional solid objects from a digital file. As the opposite of subtractive manufacturing, 3D printing allows you to produce complex and, at times, functional shapes using less material than traditional manufacturing methods.

Industries Being Disrupted by 3D Printing

Fashion — Fashion designers are using this technology to test and prototype their designs, a process that originally was expensive and inaccessible for those just entering the fashion world. High fashion designers like Anouk Wipprecht and Iris Van Herpen have created entire collections of wearable clothing using 3D printers. While on the commercial side of things, footwear companies like Adidas have incorporated 3D printing in their latest athletic shoes.

Health Care — Multiple aspects of the healthcare industry are expected to benefit from 3D printing. Like something out of a science fiction film, startups like MBC Biolabs have developed ways to actually 3D print functioning organs, while the University of Toronto researchers have created a way to 3D print skin. Some companies are already using additive technology to create prosthetics.

Food — 3D printing food may become commonplace. 3D printing food is a viable way to create meals in areas where food might not be accessible, such as space or even underwater. World-renowned Italian company, Barilla, collaborated with a Dutch research institute to bring into fruition the world’s first fresh pasta 3D printer.

Research and Development — One may overlook the benefits of 3D printing in the world of research and development. Yet, the cost of R&D is usually the most expensive part of a company’s operations dramatically affecting the bottom line. 3D printing allows companies to test and prototype much faster for a fraction of the cost.

Architecture — One of the most obvious applications of 3D printing technology can be applied to architecture in the early design process. Just like the rise of Virtual Reality (VR) technology among design agencies, 3D technology allows designers to quickly bring models to life, test ideas, and pitch concepts to clients; a part of the design process that most architects believe is the most difficult.

Construction — Companies such as PassivDom have created a process that allows homes to be built in just under 8 hours. With their own industrial robot, they can create a luxurious 3D printed house frame that could easily rival some of your apartments.

Space Travel — 3D printing is already changing the way humans travel and could even extend the duration of missions to the International Space Station and plans to Mars Whether a component on a ship was damaged during a mission or an astronaut researcher needs a new tool, 3D printing an object is far better than either carrying extra weight on a mission or requesting the needed tool, thousands of miles away.

From homes to food, 3D printing could make it significantly easier for humans to survive in space for extended periods of time, quite possibly colonize Mars.

Major Players Getting in on the 3D-Printing Game

- The Washington Post reports the US Navy is upgrading one of its aircraft carriers with 3D printing technology.

- Purdue University researchers say that Additive Manufacturing has progressed from a prototype development tool to one that can now offer numerous competitive advantages. Those advantages include shape complexity, waste reduction and potentially less expensive manufacturing, compared to traditional subtractive manufacturing where the process involves starting with the raw material and chipping away at it to produce a final result.

We’re really taking a giant leap and working on the future of manufacturing,

said Arman Sabbaghi, an assistant professor of statistics in Purdue’s College of Science, who led the Purdue research team with support from the National Science Foundation.We have developed automated machine learning technology to help improve additive manufacturing. This has applications for many industries, such as aerospace, where exact geometric dimensions are crucial to ensure reliability and safety

- Koh Kong Meng, Hewlett-Packard Southeast Asia Korea managing director says, 3D printing could facilitate distributed manufacturing, eliminating the need for big manufacturing plants.

Koh said,

[Instead], we can have a farm of 3D printers that can print the parts or products you need, when you need it. That’s the utopia of smart manufacturing. Imagine [what that means] for supply chains. There’s tremendous savings in freight and you can design products from ground zero that are strong but [require] less material.

Small to midsized manufacturers cannot afford to ignore emerging technologies like 3D Printing, Artificial Intelligence (AI), Robotics, Internet of Things (IoT), Augmented Reality/Virtual Reality (AR/VR) as the cost of all of these is plummeting. And, if you listen carefully, you can hear the footsteps of your competitors coming from behind as they are exploring these technologies.

Here at The Lake Companies, we’ve made our living helping manufacturing businesses become aware of new technology and using it to grow their businesses to make them more efficient. We are advocates of the dictum, It’s better to look ahead and prepare, than it is to look back and despair.